Understanding MCERTS: The UK's Environmental Monitoring Standard

MCERTS (Monitoring Certification Scheme) is the UK’s formal certification standard for environmental monitoring equipment and services, introduced by the Environment Agency (EA). This certification ensures that instruments and services used in monitoring emissions, pollutants, and discharges meet rigorous standards of performance, quality, and reliability. For industries operating within the environmental sector, MCERTS plays a crucial role in ensuring that environmental monitoring is carried out accurately and consistently.

MCERTS is a cornerstone of environmental monitoring in the UK, ensuring the reliability of data across industries. By certifying both equipment and services, MCERTS provides assurance that monitoring meets the highest standards. For businesses, adopting MCERTS-certified solutions demonstrates a commitment to environmental protection, regulatory compliance, and operational excellence. Whether it’s in water, air, or soil monitoring, MCERTS remains a key component in achieving sustainable industrial practices and protecting natural resources.

The Importance of MCERTS

In many sectors, such as water management, industrial emissions, and air quality monitoring, precise and reliable measurement data is critical for regulatory compliance and environmental protection. MCERTS provides a robust framework that ensures this data meets strict quality criteria. It is especially important for companies that need to demonstrate compliance with environmental legislation, such as the EU’s Water Framework Directive or the Industrial Emissions Directive.

MCERTS-certified equipment helps reduce the risk of inaccurate measurements, which can lead to violations of environmental permits or standards, potential fines, and harm to the environment. By adhering to MCERTS, Nivus show a commitment to best practices in environmental monitoring, enhancing both environmental and operational credibility.

MCERTS Certification for Equipment

MCERTS certification is awarded to a wide variety of monitoring equipment, such as:

• Air quality monitoring devices: Equipment used to measure airborne pollutants from industrial sites or emissions.

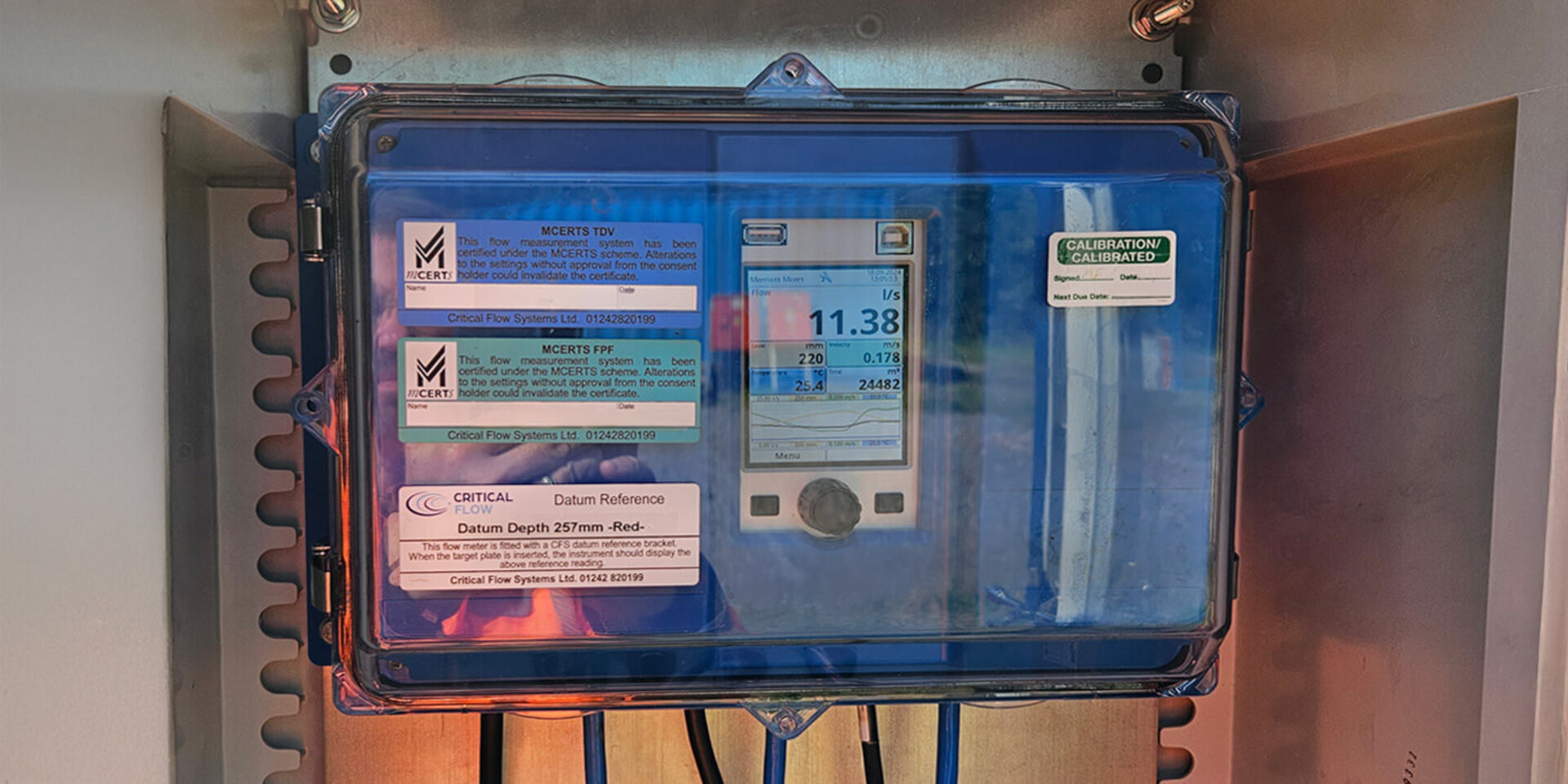

• Flow monitoring devices: NF750 Flow Transmitter

• Water quality analyzers: Devices that measure pollutants or chemical concentrations in water bodies.

The certification process involves rigorous laboratory and field testing to verify that the equipment delivers accurate and reliable data under varied operational conditions. For instance, flow measurement devices used in water and wastewater management must demonstrate they can accurately measure flow rates under full, partial, or variable flow conditions.

NIVUS > MCERTS for Closed and Open Pipe Flow Measurement

In the water and wastewater sectors, accurate flow measurement is essential for regulatory compliance. Closed and open pipe flow measurement systems certified by MCERTS help ensure that water discharge and wastewater treatment processes are accurately monitored.

Closed pipe flow measurement solutions, such as those provided by Nivus, ensure accurate readings without interrupting the flow. These systems are vital for monitoring raw and wastewater in various industrial applications. Meanwhile, open pipe and open channel measurement systems are equally critical for water management, where precise flow data is needed to ensure compliance with discharge permits and water quality standards.

NivuFlow 750 Flow Meter

Key Features and Benefits

- High-Precision Measurement for MCERTS Compliance

The NivuFlow 750 delivers MCERTS-standard measurements for both velocity and level, utilising patented cross-correlation technology to ensure highest levels of accuracy even in challenging environments, such as turbulent or low-flow conditions. This precision performance makes it ideal for sites where accurate flow verification is crucial for reporting accuracy. - Portable Design for On-Demand Verification

Lightweight and compact, the NivuFlow 750 is easily deployed across various locations, making it perfect for temporary or spot-check verifications. Its versatility allows operators to perform on-the-go measurements without a permanent installation, which is especially valuable in audits and troubleshooting situations where rapid response is essential. - Non-Invasive, Easy Installation, Battery powered

The NivuFlow 750 offers simple installation options with either wedge or insertion sensors. Using the provided universal pipe mounting or telescopic pole reduces installation time and cost while minimizing disruption. This setup allows technicians to verify flow without interrupting processes, or requiring confined-space access, making it especially useful for hard-to-reach or hazardous locations. - Advanced Data Logging and Remote Monitoring

With extensive data-logging capabilities, and impressive battery life, the NivuFlow 750 supports comprehensive monitoring and analysis over extended periods. IoT connectivity options enable engineers to access real-time data, configure remotely, or download historical data, essential for quality assurance and regulatory reporting. - Versatility Across Applications and Industries

The NivuFlow 750 is adaptable to diverse applications, from industrial wastewater monitoring to stormwater and environmental discharge. Its cross-correlation measurement approach effectively handles different flow conditions and media, ensuring compliance and accuracy across industry needs.

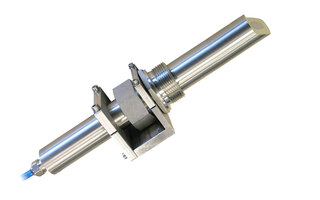

NIVUS Insertion Velocity Sensor

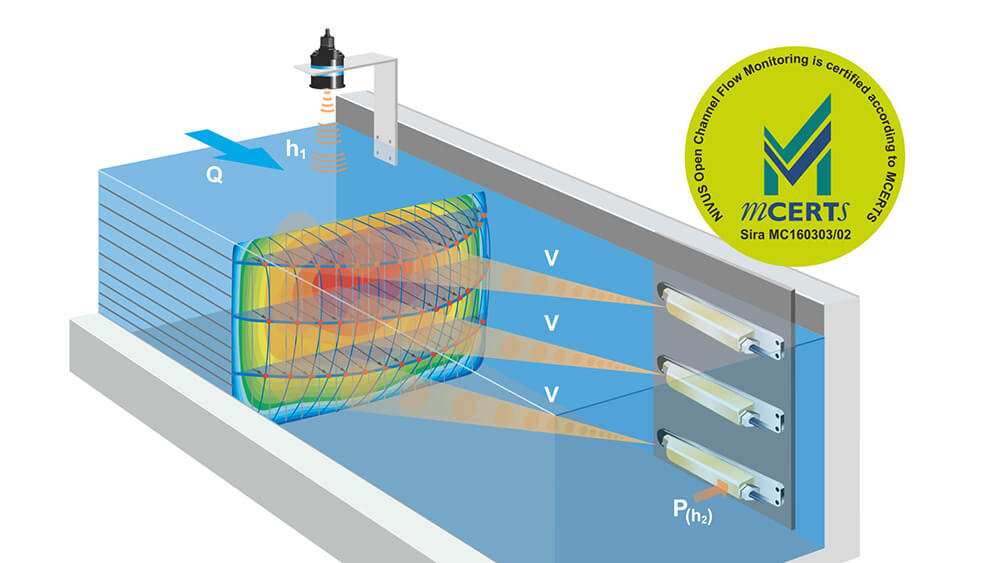

Nivus provides MCERTified AV solutions for closed pipe flow measurement, ideal for applications ranging from raw water to wastewater. Unlike Mag Flo Meters, our solutions can be installed without interrupting the flow.

Using our patented Cross Correlation technology, a single sensor accommodates pipe sizes from 150DN to 4000DN, in both partially full and fully filled conditions.

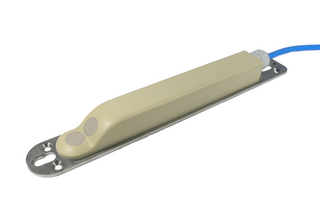

NIVUS Wedge Velocity Sensor

NIVUS provides MCERTified AV solutions for open pipe and open channel applications, ideal for applications ranging from raw water to wastewater. Using our patented Cross Correlation technology, we offer a wide range of models to meet various application needs. The NivuFlow 750 Transmitter is capable of measuring flows in both partially filled and fully filled conditions without calibration, with options for standard telemetry or device-to-web data integration.

NIVUS’ MCERTified systems, utilise Cross Correlation technology, offer industry-leading solutions by enabling measurements in both partially filled and fully filled conditions. The NivuFlow 750 Transmitter, for instance, allows continuous and real-time monitoring, with options for telemetry or web-based data sharing.

Related products

For verification purposes

Market Positioning and Competitive Advantage

Nivus positions the NivuFlow Mobile 750 as a high-accuracy, MCERTS-grade portable flow meter for the growing need for reliable, compliant flow verification. Its main competitive advantage lies in its patented cross-correlation technology, which provides a high level of accuracy that outperforms traditional Doppler-based meters in difficult conditions. Its portable design further distinguishes it from many fixed-installation solutions, making it ideal for audit and verification in compliance-sensitive industries like wastewater treatment and environmental monitoring.

Clients benefit from a solution that combines portability with precision, allowing for high-quality data collection without the need for permanent installations. In a competitive market, the NivuFlow Mobile 750 stands out by offering ease of use, flexibility, and unbeatable accuracy—all critical to ensuring compliance without compromising on performance.

Conclusion

The Nivus NivuFlow Mobile 750 is a highly adaptable, portable solution for MCERTS flow verification, offering reliable, precise measurements in alignment with regulatory standards. Its user-friendly design, combined with advanced data management capabilities, makes it an essential tool for industries requiring compliant flow verification. The NivuFlow Mobile 750 highlights Nivus’s dedication to providing innovative, high-quality measurement solutions that simplify compliance and enhance operational efficiency for engineers and environmental managers alike.

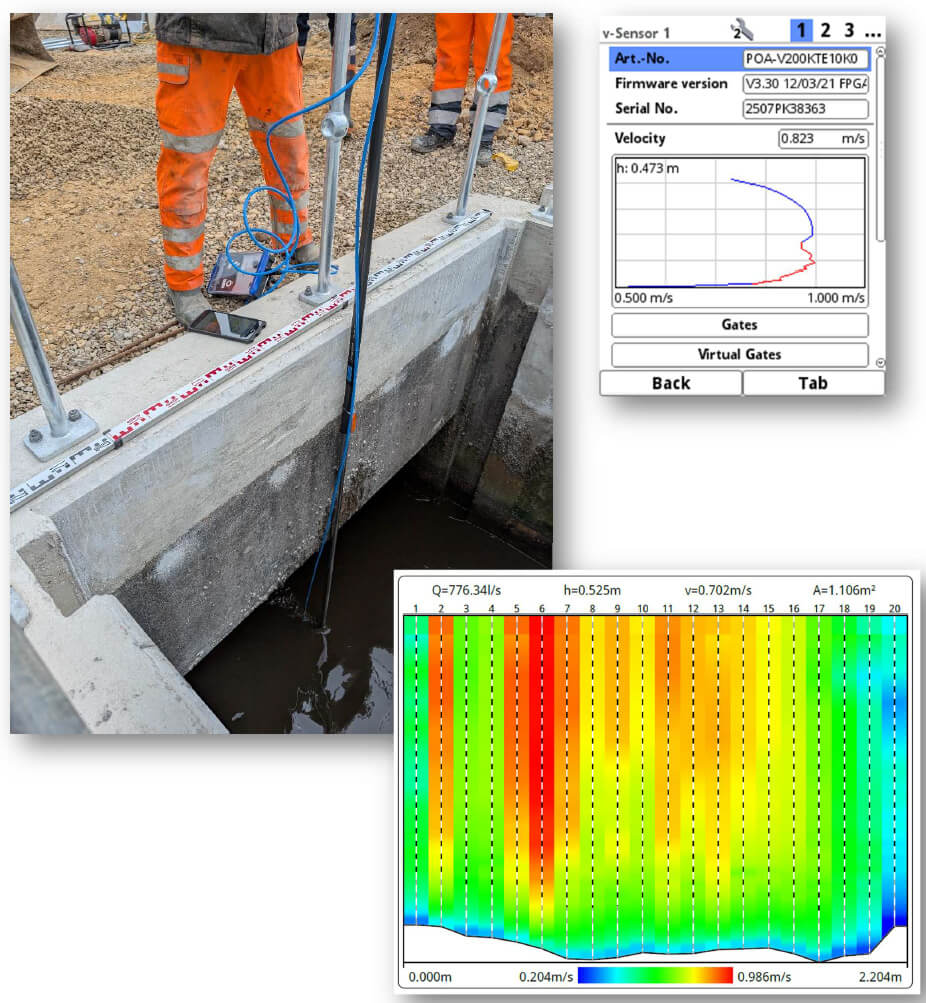

NivuFlow 550 - RADAR

The Nivus Radar Velocity Profiler sets a high standard in MCERTS-compliant flow measurement solutions, leveraging radar technology and advanced data profiling to achieve precise and reliable measurements in open channels and partially filled pipes. Its certification assures users of the highest compliance and performance standards, making it ideal for applications where regulatory adherence is critical.

Key Strengths and Benefits

- MCERTS-Certified Non-Contact Measurement

NIVUS’s radar-based approach allows for non-contact flow measurement, eliminating issues associated with submerged sensors, such as maintenance, sediment accumulation, and sensor degradation. his makes it exceptionally durable in challenging environments, reducing maintenance demands and ensuring sustained MCERTS-compliant performance, even in tough field conditions. - High Accuracy and Reliability

The profiler’s radar technology, certified for MCERTS standards, provides highly accurate measurements across a range of velocities, even in complex hydraulic conditions. This allows users to rely on precise, compliant data in critical applications, such as wastewater management and industrial monitoring, where regulatory adherence is key. - Detailed Flow Profiling for Enhanced Accuracy

The Nivus profiler captures surface velocity measurements to build a detailed flow profile, significantly enhancing flow volume calculations. This ability to create an accurate flow profile is particularly useful for large-scale or complex channels, adding a layer of certified precision that is essential for hydraulic modelling and large infrastructure projects. - Minimal Maintenance and Long-Term Compliance

Unlike submerged alternatives, the non-contact Nivus profiler requires minimal maintenance, which translates into reduced downtime and lower operational costs without sacrificing data integrity. Its certified reliability offers long-term compliance with regulatory standards, making it a cost-effective choice for clients seeking to balance efficiency with compliance. - Advanced Data Processing and Seamless Integration

Equipped with advanced data processing capabilities, the profiler integrates seamlessly with SCADA and other monitoring systems, enabling real-time data visualisation and regulatory reporting. The MCERTS certification assures that this data meets compliance standards, giving operators confidence in its accuracy and reliability. - Versatile, MCerts - Compliant Applications

The NIVUS Radar Velocity Profiler serves a wide range of applications, including industrial wastewater, environmental monitoring, and urban drainage. Its MCERTS-certified status provides assurance that it meets strict regulatory standards, adding value for customers in highly regulated sectors and making it a trusted solution for industries that prioritize certified equipment.

Related products

For verification purposes

MCERTS Certification for Services

In addition to equipment, MCERTS also certifies environmental monitoring services. This includes the calibration, installation, and maintenance of monitoring equipment. NIVUS provide comprehensive field services to demonstrate a high standard of expertise and knowledge in maintaining the integrity of environmental monitoring data.

NIVUS provides an end to end solution delivery across the UK and EMEA. With a team of dedicated and experienced engineers, we manage every aspect of the delivery process, including design and consultancy, specification guidance, surveys, feasibility studies, installation, and commissioning services. Additionally, we also offer interim health check monitoring, performance analysis, and verification services to ensure optimal system performance.

NIVUS, as a service provider follows best practices, ensuring the equipment is set up correctly and continues to function optimally over time. This guarantees that the data collected is reliable for regulatory reporting.

Benefits of MCERTS Certification

- Regulatory Compliance: MCERTS certification helps businesses meet environmental regulations, which reduces the risk of non-compliance, penalties, or environmental harm.

- Data Accuracy: Certified equipment and services guarantee high-quality, reliable data, which is crucial for decision-making, regulatory reporting, and operational efficiency.

- Environmental Responsibility: By using MCERTS-certified products, companies demonstrate a commitment to environmental stewardship and best practices.

- Market Confidence: Having MCERTS certification boosts credibility in the marketplace. Clients, regulators, and stakeholders have confidence that certified equipment and services meet stringent environmental standards.

- Cost Efficiency: Reliable data collection reduces errors and rework, saving time and money in the long term by preventing issues related to inaccurate environmental monitoring

Customer Testimonial: Why We Chose NIVUS for Our Flow Measurement Needs

"We’ve been using NIVUS flow measurement solutions for over a year now, and the difference in performance and reliability has been remarkable. As a company managing complex wastewater and water treatment processes, accurate flow data is absolutely essential for us to meet regulatory requirements and ensure operational efficiency.

One of the key reasons we chose Nivus was their MCERTified technology. It gave us confidence knowing that their solutions met the highest standards for environmental monitoring. Their patented Cross Correlation technology has been a game changer. It allows us to get precise measurements in both partially filled and fully filled pipes, without any interruptions to our flow. This was a significant advantage over other systems we’ve used in the past, which required downtime during installation.

Nivus' team of engineers were with us every step of the way, from initial design to installation and commissioning. Their expertise and customer support have been exceptional. We can now monitor real-time data, with options for telemetry and web-based integration, giving us full control and oversight of our operations.

If you're looking for a reliable, innovative, and easy-to-integrate solution for flow measurement, NIVUS should be your top choice. Their products and service have exceeded our expectations, and we look forward to continuing our partnership with them for years to come.”

Cross Correlation Technology by Nivus: The Ultimate Solution for Challenging Flow Measurement

In the realm of flow measurement, accuracy and reliability are paramount, particularly when dealing with challenging conditions such as turbulent flows, variable pipe fills, and changing fluid properties. NIVUS, a leader in innovative measurement solutions, has developed its patented Cross Correlation technology to tackle these challenges effectively. This article explores why Cross Correlation technology is the ultimate choice for measuring flow under demanding circumstances.

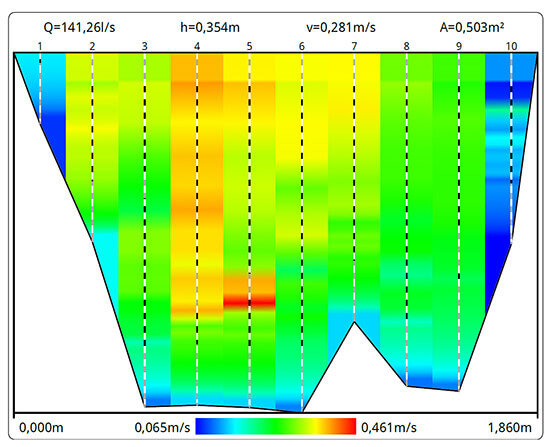

Understanding Cross Correlation Technology

Cross Correlation technology is a sophisticated measurement method that analyses the time delay between two signals to determine flow velocity. Unlike traditional flow measurement techniques that rely on direct pressure or electromagnetic sensing, Cross Correlation evaluates flow dynamics by comparing two distinct patterns in the flow, using sensors capable of profiling the entire water column.

This method provides precise flow measurements even in turbulent or fluctuating conditions, making it particularly beneficial for a range of applications, including wastewater treatment, industrial processes, and water resource management.

Functional Principle Cross Correlation

Advantages of Cross Correlation Technology

1. High Accuracy in Varied Conditions

One of the standout features of Cross Correlation technology is its ability to maintain high accuracy across a wide range of flow conditions. Whether the flow is turbulent, partially filled, or fully filled, NIVUS’s Cross Correlation systems deliver consistent and reliable data. This flexibility is crucial in real-world applications where flow conditions can change rapidly due to operational demands or environmental factors.

2. Non-Intrusive Measurement

NIVUS’s Cross Correlation technology operates in a non-intrusive manner, allowing for flow measurement without interrupting the process. This feature is especially beneficial in applications where maintaining continuous flow is essential, such as in wastewater treatment plants and industrial pipelines. Traditional measurement methods that require flow interruptions can lead to costly downtime and operational inefficiencies.

3. Wide Range of Pipe or Channel Sizes

The Cross Correlation technology is versatile enough to accommodate a wide range of geometries, pipes, rectangle channels to trapezoidal or even custom inputs. As a guide we can measure flows in as little as 100mm up to 6000mm. This adaptability ensures that it can be applied in various settings, from network sewer systems to large-scale industrial applications, without the need for different measurement solutions.

4. Robust Performance in Challenging Environments

Many flow measurement technologies struggle in environments characterised by noise, turbulence, or changes in fluid density. Cross Correlation excels in these challenging conditions, providing accurate measurements where traditional technologies may fail. Its ability to filter out background noise ensures that operators receive clean, actionable data, which is vital for making informed decisions.

5. Real-Time Monitoring and Data Integration

NIVUS’s Cross Correlation technology offers real-time monitoring capabilities, enabling operators to track flow conditions continuously. This immediate feedback is crucial for maintaining compliance with environmental regulations and operational efficiency. Additionally, the technology can be easily integrated into existing monitoring systems, allowing for seamless data transfer and analysis.

6. Cost-Effective and Efficient

By providing accurate and reliable measurements without the need for frequent recalibration or maintenance, Cross Correlation technology ultimately reduces operational costs. Its non-intrusive nature also minimizes downtime, further contributing to overall efficiency and cost savings for businesses.

Applications of Cross Correlation Technology

The versatility of NIVUS’s Cross Correlation technology makes it suitable for a variety of applications, including:

- Wastewater Treatment: Accurately measuring flow rates in treatment plants ensures compliance with discharge permits and effective treatment processes.

- Industrial Processes: Maintaining consistent flow measurements in manufacturing and processing operations helps optimize production and resource management.

- Water Resource Management: Effective measurement of river and canal flows supports effective water resource allocation and environmental monitoring.

Conclusion

In a landscape where precision in flow measurement is increasingly vital, NIVUS’s Cross Correlation technology stands out as the ultimate solution for challenging flow conditions. Its ability to provide accurate, reliable, and non-intrusive measurements across diverse environments makes it an invaluable asset for industries facing complex flow scenarios.

As companies strive to enhance operational efficiency, ensure regulatory compliance, and promote environmental stewardship, NIVUS’s Cross Correlation technology offers a proven and innovative solution to meet these demands. Whether in water management, wastewater treatment, or industrial applications, NIVUS equips you with the tools necessary to tackle flow measurement challenges confidently.