English (UK)

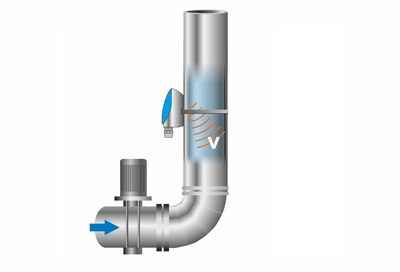

Flow Rate Monitoring on Pumps

Channel Networks - Pump Stations and Lifting Facilities

Application

- Cast iron pipe DN 200

- Full filled

- Old existing line (condition unknown), installed pipe system cannot be modified

Definition of tasks

- Flow rate monitoring of feed pump to detect clogging and dry run

- Tendency monitoring of feed pump to detect wear and tear

- Optimisation of repair and maintenance intervals

- No high accuracy required (permissible error higher than 10 %)

- Good reproducibility

Advantages

- Direct connection to the PLC available on site (no transmitter required)

- No modification of old pipeline necessary