Flow Meter

NivuFlow 7550

Part No. N75-5Hybrid Flow Measurement with Surface Radar and Ultrasonic Profile Scanner

Flow measurement for open channels as well as part filled pipes. Optimum results through combination of ultrasonic cross correlation and radar technology.

- Redundant flow measurement

- Contactless Radar surface velocity measurement

- Ultrasonic sidewards velocity profile sensor

- Two independent flow measurement technologies increase the accuracy and reliability

- All sensors are above the area of sedimentation,

- No maintenance

- Reliable measurement independent of wave formations, storm conditions, as well as in low flow level circumstances

- Self-learning system with stored dynamic hydraulic models

- IoT-ready with global 4G connectivity for highest availability and digital services

Hybrid Flow Measurement

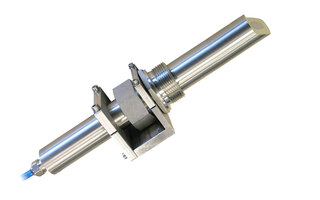

NivuFlow 7550 is a hybrid measurement system which was particularly developed for flow metering in part filled pipes, channels and surface waters. Mainly in difficult applications the flow meter stands out for reliable results thanks to its advantages by using two measurement technologies.

Contactless Radar Flow Measurement

The contactless low-maintenance radar sensor provides reliable operation even at very high discharge velocities with low flow levels. Dynamic hydraulic models for various channel shapes based on varying filling levels enable accurate detection of the real flow rate.

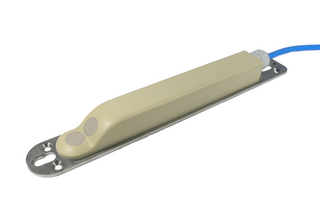

Ultrasonic Flow Measurement as Overflow Sensor

The ultrasonic cross correlation sensor can be used as overflow sensor. In such cases the sensor provides reliable and accurate results in overflow situations where radar sensors cannot be used for measuring. Thanks to the flow profile detection and the detection of sedimentation on the bottom the flow rate is determined very accurately. Information on sedimentation is also considered for further measurements using the radar system.

Ultrasonic Flow Measurement as Redundant Measurement

The ultrasonic sensor can be used as permanent redundant measurement too. Installing the sensor on the side walls above the sedimentation helps to avoid soiling. The detection of local flow velocities covers the entire channel width and guarantees the determination of very accurate flow profiles. Pre-programmed hydraulic models increase the accuracy of the measurement system.

Easy Installation and Handling

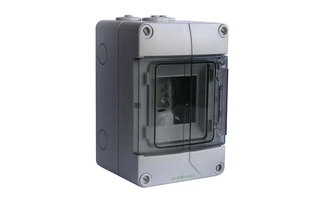

Due to DIN rail mounting options the compact transmitter saves space and can be installed easily in control cabinets. Moreover the NivuFlow 7550 is available with a special protected field enclosure for use under harsh ambient conditions. The large graphic display permits quick and easy commissioning of the flow meter system.

NivuFlow 550 provides extended diagnostic options and facilitates in-depth analysis of running processes on site. The transmitter software is in line with current requirements. Future-proof protocols and versatile communication and integration options open many ways for operators to integrate the devices into higher systems such as SCADA or process control systems.

Typical NivuFlow 7550 Applications

- Continuous and reliable flow metering in overflow situations

- Sedimentation detection with ultrasonic level measurement in case of overflow

- Measurement places featuring high dirt loads and sedimentation

- Measurement places featuring bed load / debris

- Measurement places with limited installation options within the channel

- Reliable flow metering in shooting discharge and low flow levels

| Common | |

|---|---|

| Power supply | 100 to 240 V AC, +10 % /-15 %, 47 to 63 Hz or 9-36 V DC |

| Power consumption | 14 VA typical |

| Enclosure |

|

| Protection | IP 20, IP 68 with optional field enclosure |

| Operating temperature | −20°C to +70°C |

| Max. humidity | 80%, non-condensing |

| Display | 240 x 320 pixel, 65536 colours |

| Range of operation | rotary pushbutton, 2 function keys, menus in English, French and other languages |

| Connection | plug with cage clamp terminals |

| Inputs | up to 7 x 4 - 20 mA, up to 4 x RS 485 |

| Outputs | up to 4 x 0/4 – 20 mA, up to 5 x relays (SPDT) |

| Data memory | 2.0 GB internal memory, flexibly expandable, readout on faceplate via USB stick |

| Communication (optional) | Modbus, HART® |

| Measurement uncertainty | flow (Q): ± 5% typical; ± 2% under reference conditions |

| Measurement principle | radar in combination with ultrasonic crosscorrelation |

Specifications subject to change.

Instruction Manual | NIVUS Data Transmission of Devices NivuFlow 7550 and Energy Saver - Supplement to the respective Instruction Manual (Rev. 02)

EU Declaration of Conformity | Permanent flow measurement transmitter with internal modem for remote data transmission NivuFlow 7550

Typ N75-xG...

![[Translate to English:] Hybriddurchflussmesser NivuFlow 7550 [Translate to English:] Hybriddurchflussmesser NivuFlow 7550](/fileadmin/_processed_/1/6/csm_NivuFlow_7550_schraeg_01_b4c7bad0e1.jpg)

![[Translate to English:] Überstausensor in Kombination mit Radardurchflussmessung [Translate to English:] Überstauensor in Kombination mit Radardurchflussmessung](/fileadmin/_processed_/9/e/csm_surchargesensor1nosurchargecondition_2ea28e1564.jpg)

![[Translate to English:] Überstaudurchflussmessung [Translate to English:] Überstaudurchflussmessung](/fileadmin/_processed_/8/d/csm_surchargesensor2surchargecondition_2f12a0631a.jpg)

![[Translate to English:] Hybriddurchflussmessung Radar und Ultraschallkreuzkorrelation [Translate to English:] Hybriddurchflussmessung Radar und Ultraschallkreuzkorrelation](/fileadmin/_processed_/f/c/csm_redundantflowmeasurement_8bcbc8da79.jpg)

![[Translate to English:] Durchgängiges Kommunikationskonzept [Translate to English:] Durchgängiges Kommunikationskonzept](/fileadmin/_processed_/8/b/csm_Communication-concept_b09d9b3894.jpg)

![[Translate to English:] Feldgehäuse für NivuFlow Messumformer [Translate to English:] Feldgehäuse für NivuFlow Messumformer](/fileadmin/_processed_/8/d/csm_NivuFlow-Fieldenclosure_ce627ed36a.jpg)