Flow Measurement using Ultrasonic Cross Correlation

- Scientifically tested, channelspecific mathematical flow models

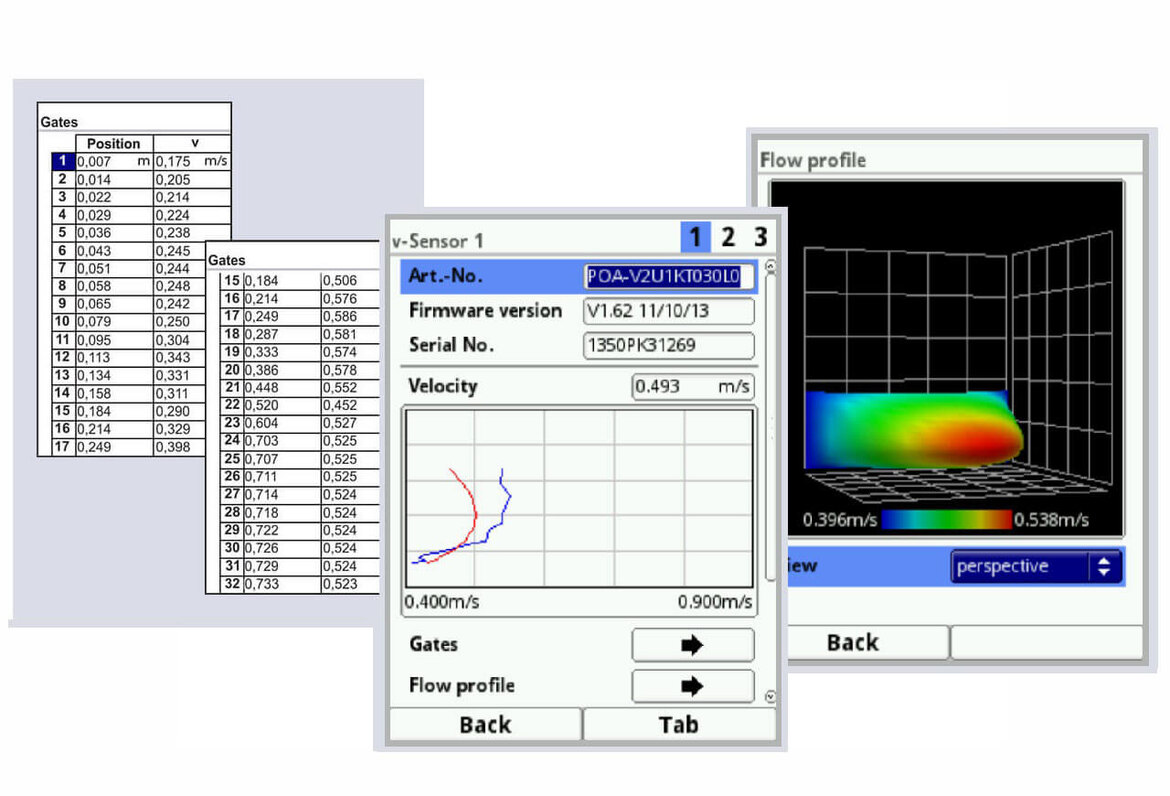

- Calculation of the near-wall flow velocity distributions and the horizontal velocity profile

- Velocity integration over the entire cross-section

- Ideal for determining the average flow velocity even with hydraulically disturbed channels

Measurement Method

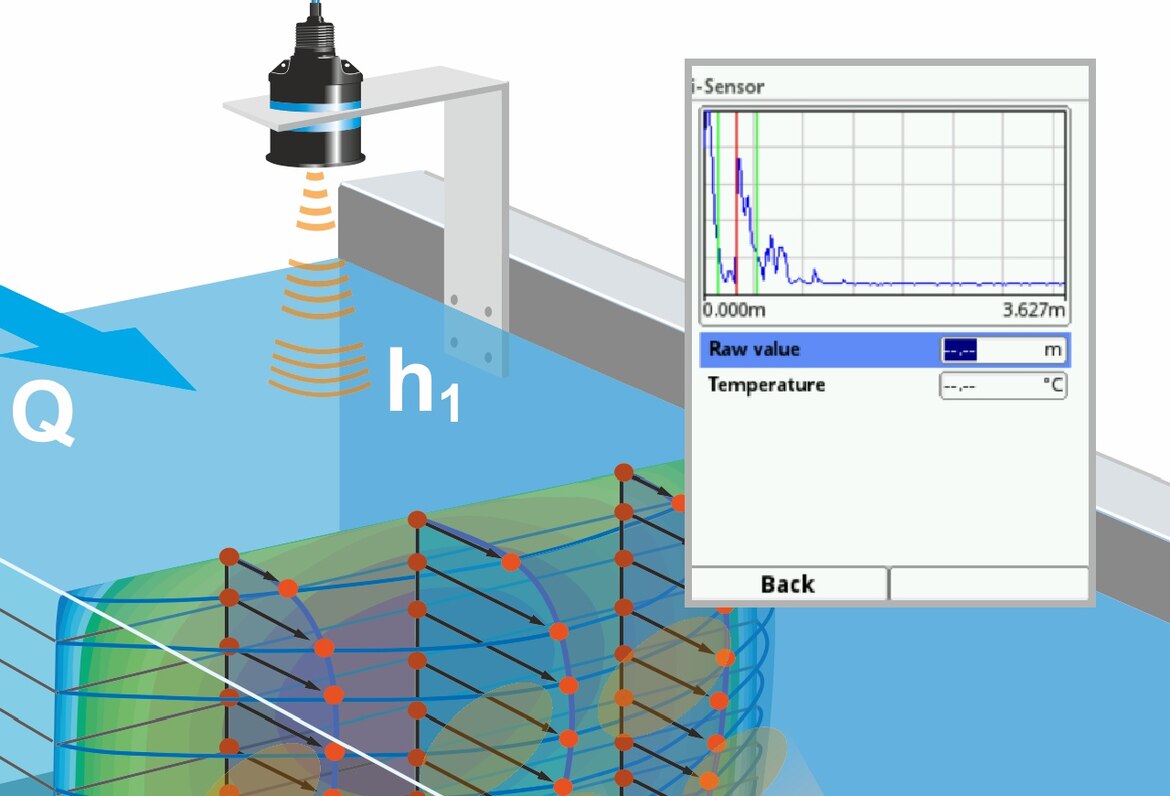

Flow cannot be measured directly. Multiple factors are required to detect the flow Q: average flow velocity v (average) and the flow cross section A which leads to the general formula:

Q = v (average) • A

The flow cross section A is investigated by continuously measuring the filling level considering the channel shape.

The flow velocity is detected by using the particles‘ velocity. Most media contain a certain load of dirt particles or gas bubbles which move in the same velocity as the liquid itself.

Your Benefits

- Highest measurement accuracy even under backwater conditions

- Stable readings

- No calibration required

- Determination and indication of flow profiles at the measuring point

Flow Velocity Measurement (v) using Cross Correlation

The measurement method used for flow velocity determination is based on the principle of ultrasonic reflection. One of the most modern and most efficient measurement methods for flow velocity detection is the NIVUS cross correlation method.

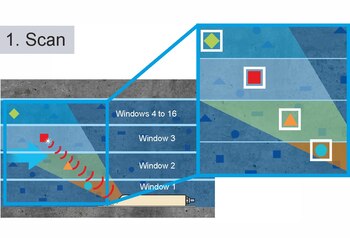

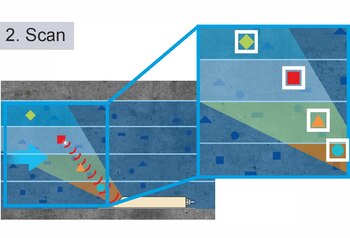

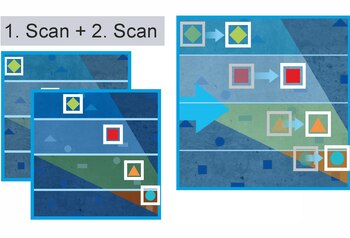

Existing reflectors within the medium (particles, minerals or gas bubbles) are scanned using an ultrasonic impulse with a defined angle. The resulting echoes are saved subsequently as images or echo patterns.

By correlating/comparing the saved signals, the positions of unambiguously identifiable reflectors can be identified. The reflectors can be identified at varying positions within the images since they have moved with the medium.

Considering the beam angle it is possible to directly compute the particle velocity and hence the medium flow velocity from the temporal shift of the reflectors. This allows to obtain highly accurate readings without the need to perform additional calibration measurements.

Functional Principle Cross Correlation

Level Measurement (h)

Accurate flow measurements require precise and reliable determination of levels under all hydraulic conditions. Based on our many years of experience we developed a multiply redundant level measurement system. The combination of hydrostatic measurement, water-ultrasound and air-ultrasound provides solutions for all measurement tasks.

Moreover external 0/4 - 20 mA level sensors such as „i-Series“-sensors or NivuBar Plus can be connected.