02-16-2015

NIVUS is Finalist at Environment and Energy Awards

The NIVUS pipe sensor flow meter concept made it to the shortlist of Environment and Energy Awards. Our entry to the Innovative Water Management and Efficiency Award category did a great job of impressing the judges and NIVUS is just one step before being awarded the winner’s trophy at the prestigious awards ceremony on Wednesday 22nd April 2015.

The NIVUS Flow Meter Solution

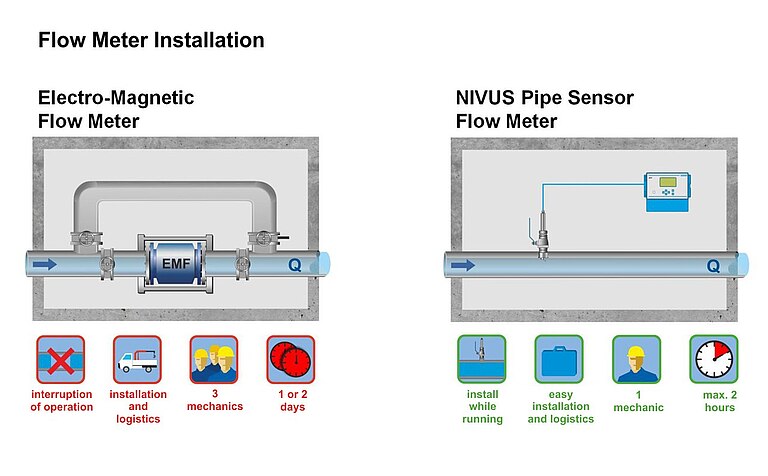

Flow meters are low CAPEX but can be high install cost because of valving and installation requirements. They also have high replacement cost, due to shutdown needs, and the over–pumping / ancillary equipment needed to allow the shutdown. There’s also a high carbon demand for installation.

The MCERT approved ultrasonic meter from NIVUS can be fitted while the process is still running, using a hot tap fitting, valve, and push through pipe probe. Core CAPEX cost for meter and probe looks higher than mag meter but the install and replace costs are very significantly lower as well as carbon demand.

The advantages of the ultrasonic Pipe Sensor solution from NIVUS were obvious. So it was easy to convince customers for the new technology:

Greatest carbon reductions

The mag flow meter requires isolating valves for future removal and replacement, and for large meters and large valves this also requires cranes and lifting procedures. Over-pumping is frequently required as part of the install. Access chambers will also be smaller for the new design meter.

Tremendously Faster installation

Time on -site to fit can be significantly reduced. Mag flow meter involved shutdown of plant for several hours over 3 days and significant preparation time. Fitting two trial flowmeters including hot tapping took a total of 3 hours with no shutdown required. A major impact plan for installation / replacement could become a minor impact plan.

The Innovation behind the Product

NIVUS Cross Correlation patented technology stands in the same range of accuracy compared to Mag Meters. The Pipe Sensor (insertion flow meter) is compact by design, one size sensor for all diameters, manufactured for a low carbon footprint, and suitable for partial or full pipes. Maintenance is easy for low pressure pipes and with a special insertion and removal tool designed it’s also easy for pipes under pressure. When cost and time savings are paramount as is accuracy of data, the Pipe Sensor is the smart choice for the validation and/or replacement of Mag Meters.

Using ultra sonic cross correlation flow measurement over mag meters is thinking beyond the edge of the traditional and using existing technology for a better carbon footprint of systems.