Ultrasonic Doppler Flow Measurement

Doppler Method

- For slight to heavily polluted media

- For simple applications

- Cost-efficient entry point into flow measurement

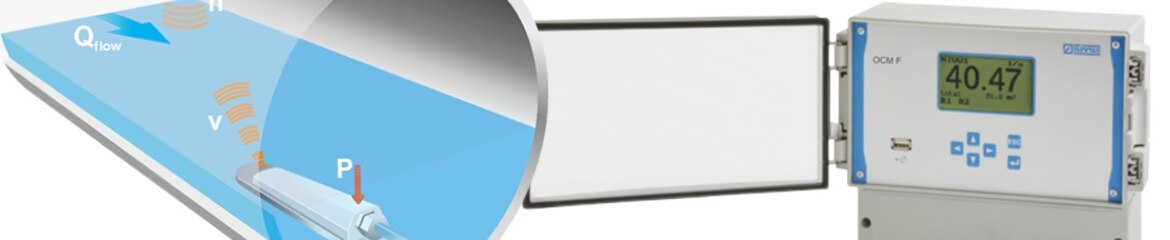

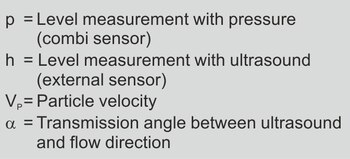

Average flow velocity and flow cross section are required to determine the flow Q. This leads to the general formula:

Q = v (average) • A

The flow cross section A is determined by continuously measuring the filling level taking the channel shape as well as the channel dimensions into account. Most media contain a certain load of dirt particles or gas bubbles which move in the same velocity as the medium itself. The flow velocity is determined by measuring the velocity of the particles using an ultrasonic signal.

Your Benefits

- Easy installation without the need for additional constructions

- Measurement in heavily polluted and abrasive media

- Reliable and fail-safe, 30 years of product experience at NIVUS

Flow Velocity Measurement (v) using the Doppler Method

The measurement principle is based on the classic Doppler method with an ultrasonic signal being sent into a liquid with a defined frequency and in a known angle.

Portions of the ultrasonic energy are reflected from the particles or gas bubbles contained within the liquid.

This results in a frequency shift due to the particle movement. The frequency shift is direct proportional to the particle velocity, which in turn allows determination of the flow velocity. A frequency spectrum results from the numerous reflecting particles and the flow profile. This spectrum is indicated on the transmitter display and can be used for hydraulic assessment of measurement places. Based on proven mathematical algorithms the intelligent Doppler sensor evaluates the average flow velocity from the frequency spectrum.

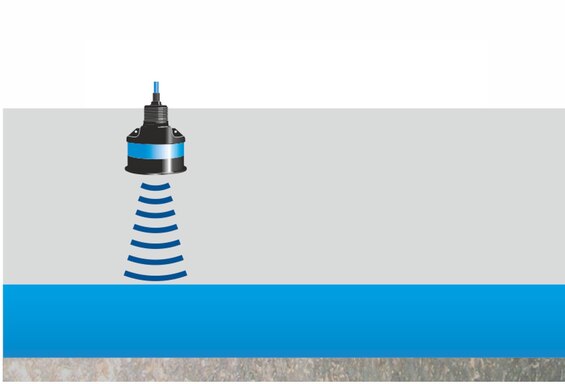

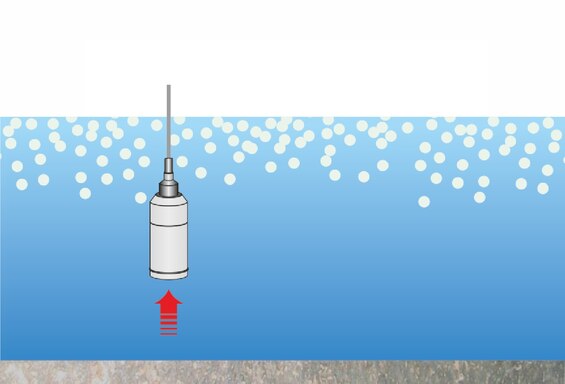

Accurate flow measurement requires precise and reliable determination of levels under all hydraulic conditions.

The level can be measured by using the flow velocity sensor's built-in pressure sensor. Alternatively, external sensors such as the contactless ultrasonic "i-Series" sensors or hydrostatic sensors such as NivuBar Plus can be used as well.