- Very high accuracy by means of ultrasonic cross correlation method

- Interference-free connection over long distances through digital signal transmission

- Cable extensions over several 100 metres with standard cables possible without any problems

- Absolutely stable zero point and drift-free

- Measurement in slightly to heavily contaminated media

- Suitable for media with high solids loads

- Easy installation without additional constructions thanks to optimised mounting accessories

- Installation under process conditions possible

- Particularly suitable for pipe sections starting at 1000 mm diameter

The pipe sensors are designed for mounting from the outside into the pipelines using nozzles. In combination with transmitters such as NivuFlow 750 or NivuFlow 7550 and an additional external level measurement, they form a complete flow measurement system for part filled applications. They can also be used for permanently full pipes or Channels. The additional height measurement can be omitted here.

Typical applications for CS2 pipe sensor

- Channel networks: billing measurement places, flow measurement in large pipe sections

- Wastewater treatment plants: intake, discharge, activated sludge tank intakes, return sludge, recirculation, surplus sludge, digester discharge and flocculant dosage

- Pump stations: pumped quantities

- Industrial wastewater networks

- and many more

| General | |

|---|---|

| Construction | Pipe sensor for installation in pipes with sensor screw joint and retaining element |

| Measurement principle | Ultrasonic Cross Correlation with digital pattern detection (flow velocity)

|

| Protection | IP 68 |

| Ex-Approval |

|

| Operating temperature |

|

| Storage temperature | −30 °C to +70 °C |

| Operating pressure | max. 4 bar (for combi sensors with pressure measuring cell max.1 bar) |

| Cable lengths | 10/15/20/30/50/100 m pre-configured, can be extended upon request |

| Cable types | LiYC11Y 2 x 1,5 + 1 x 2 x 0,34 PA 1,5/2,5 |

| Outside cable diameter | 8.4 mm ±0.25 mm |

| Sensor connection | Cable end pre-configured for connection to NivuFlow 750 |

| Sensor types | v-sensor with T-compensation |

| Medium-contacting materials | Polyurethane, stainless steel 1.4571, PPO GF30, PTFE, PA6 GF30 Optional sensor resistant to chemicals made of PEEK, sleeve made of Hastelloy C-276; cable with FEP coating |

| Zero point drift | absolutely stable zero point |

| Measurement frequency | 1 MHz |

| Measurement range | −100 cm/s to +600 cm/s |

| Max. Measuring span | Δ 700 cm/s |

| Measurement range | −20 °C to +60 °C |

| Measurement uncertainty |

|

Specifications subject to change.

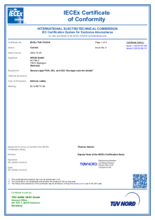

EC type examination certificate sensor type POA, OCL and CS2

EC type examination certificate sensor type POA incl. supplement

![[Translate to English:] Installation Durchflussmessung - Vergleich bei DN 800 [Translate to English:] Durchflussmessung - Installationsvergleich](/fileadmin/_processed_/8/0/csm_Durchflussmessung-Rohrsensor_b7a18d158d.jpg)

![[Translate to English:] Durchflussmessung Ultraschall Kreuzkorrelation [Translate to English:] Durchflussmessung Ultraschall Kreuzkorrelation](/fileadmin/_processed_/9/1/csm_Cross-Correlation-Priniciple-Pipe_8b0e2b98b8.png)