Flow Meter

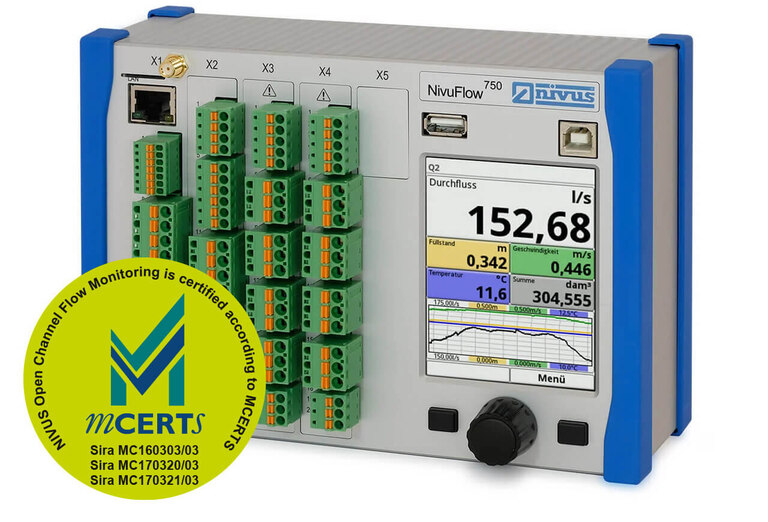

NivuFlow 750

Part No. NF7Flow measurement with cross correlation technology

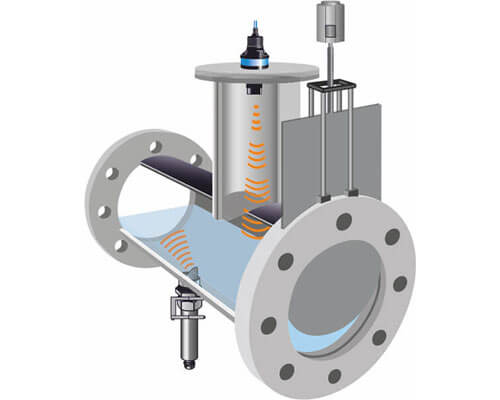

For ultrasonic flow measurement of slight to heavily polluted media in part filled and full pipes and channels. Best possible results even under difficult conditions.

Flow measurement systems at the highest technical level

- Very high accuracy flow meter by means of ultrasonic cross correlation method

- Also suitable for the most difficult applications

- Measurement of the real flow velocity profile

- Up to 32 individual velocities per sensor

- Integrated, scientifically developed flow models

- Worldwide connectivity for commissioning, maintenance, data transfer and service

- Extensive diagnostic functions for safe and fast commissioning and maintenance

- Self-monitoring and self-diagnosis with status output in accordance with Namur NE 107

- Cycle operation for autonomous measurements

- Combination of several partial measurement points with different measurement methods in one overall measurement

Innovation, reliability and maximum accuracy

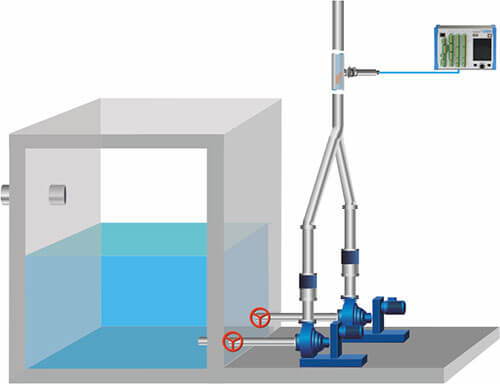

Together with the sensors, the NivuFlow 750 forms a stationary measuring system for continuous flow measurement and flow control for low to heavily contaminated media of various compositions.

It is used in part filled and full flumes, canals and pipes of various geometries and dimensions. The measurement transducer is able to record the current flow rate at a maximum of 3 different measuring points with up to 81 flow velocity sensors.

Typical Applications

- WWTPs

- channel networks

- discharge constructions

- industrial wastewater networks

- measurement places for billing

- intakes

- drainage lines

- return sludge lines

- recirculation lines

- and many more

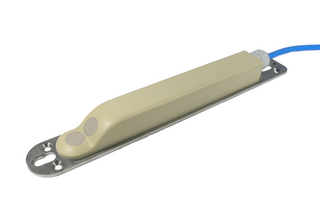

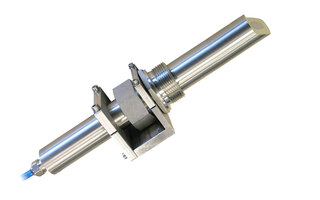

The right sensor for each application

A wide selection of sensor designs is available for measuring flow velocity and flow level in flumes, pipes and canals ranging from very small to several metres in size: Flow velocity sensors with and without integrated flow level measurement as well as air-ultrasonic flow level sensors.

Highly resistant sensors in PEEK design with Hastelloy mounting plates or in titanium design and FEP-protected cables withstand even highly aggressive and corrosive environments.

Your benefits

- Absolutely zero point stable and drift-free sensors

- Low installation expenses through perfectly matched mounting accessories

- Installation under process conditions

- Various sensor constructions guarantee the best solution for each application

- Digital signal transmission for errorfree connections over long distances

- Ex approval Zone 1

Application Examples

Pump Stations

- Quick and easy retrofitting to all pipework materials

- No cutting or dismantling of existing pipes

- Reliable and accurate measurement of slightly polluted media through to to sludge

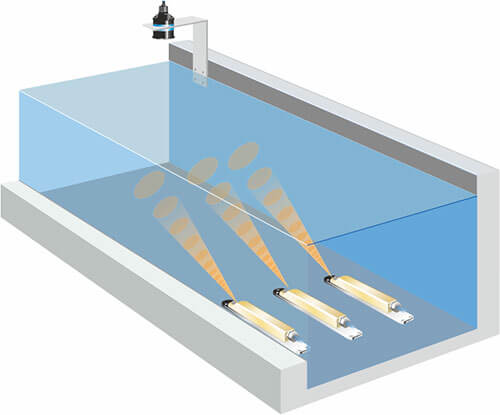

Control Measurement Section

- Measurement and control of transfer volumes in rainwater treatment plants

- Reliable and accurate recording of night-time discharges, dry and rainwater volumes

- Intelligent control algorithms for surge detection, quick close and flush-free as well as automatic flushing functions

- Easy integration into higher-level sewer management systems

Measurement Places for Billing

- Equipment for calibrated and certified billing measuring points, e.g. for industrial dischargers

- Highly accurate multi-path systems with up to 288 precisely positioned individual flow velocities in the flow profile

- Absolutely zero-point stable and drift-free measuring system without interference from sieve skins, grease films, etc.

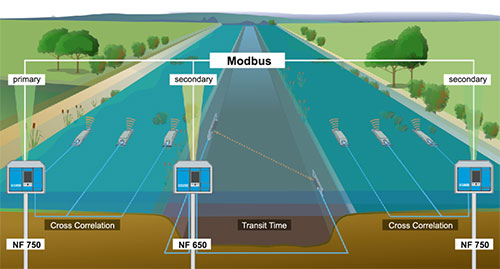

Multi Measurement Places

- Combination of different measuring methods at complex measurement places

- Multiple measuring point capability

- Integration option for up to 81 flow velocity measurement sensors

- Modbus coupling of all NivuFlow transmitters

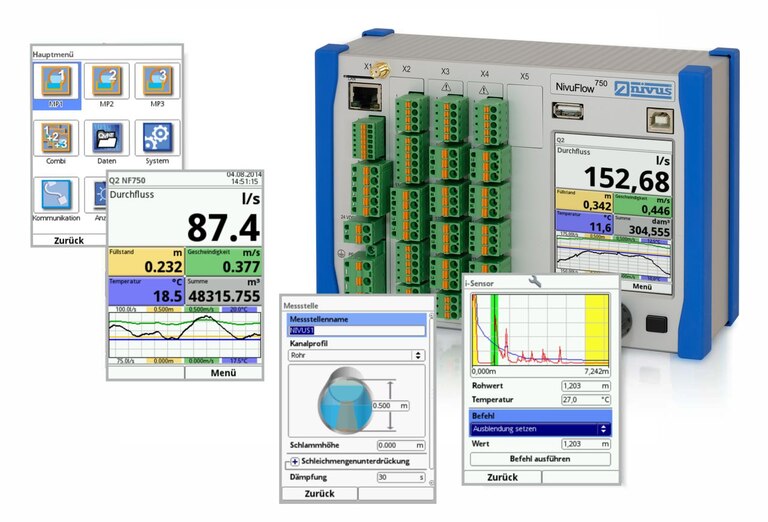

Nivu Flow 750 - Universal transmitter

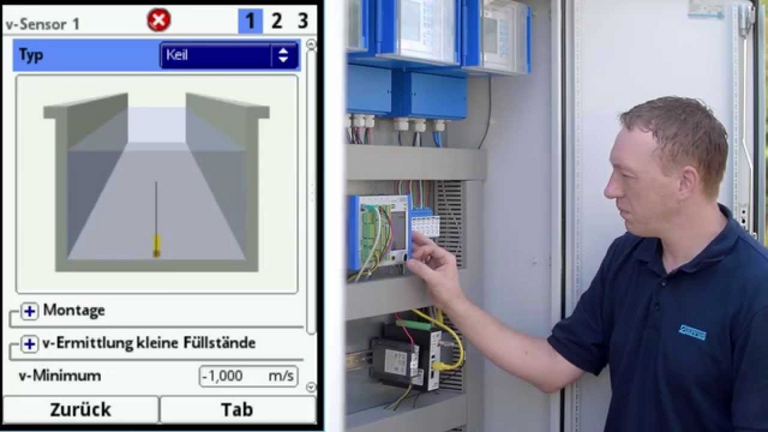

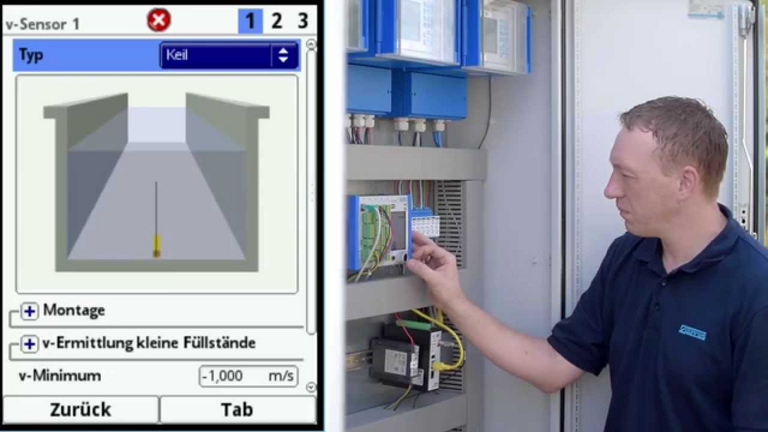

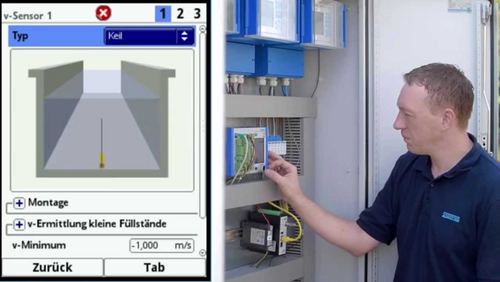

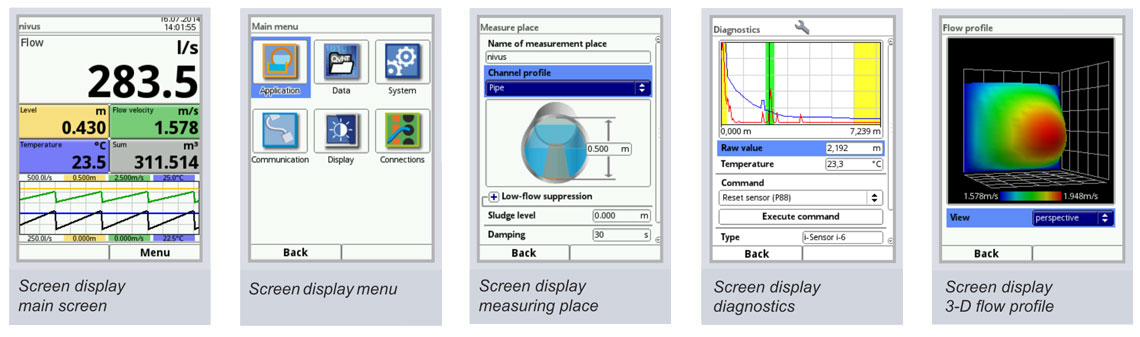

The intuitive one-hand operation and the bright high-resolution colour display allow quick, easy and cost-efficient commissioning on site. Additional input devices or software are not required. The latest integrated numeric discharge models enable more accurate, more stable and more reliable determination of flow rates even under very difficult measurement conditions.

The 3D flow profile is calculated in real time and is reproducibly and verifiably indicated on the transmitter display. Factors influencing the calculation results such as channel shapes, discharge behaviour and wall roughness are considered during flow calculation.

Delayed discharge behaviour and variable backwater effects are reliably recorded and taken into account in the calculation.

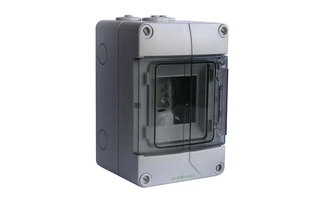

In addition to the compact DIN rail version there is a weatherproof field unit available featuring appropriate connection space for outdoor installation.

Sensor Monitoring and Self Diagnostics

An integrated, fully automatic evaluation algorithm allows a continuous check for any maintenance requirements or a necessary check of the measurement system.

A Namur NE 107-compliant diagnosis and status evaluation informs the operator about maintenance requirements, wear, sensor damage or destruction, as well as spillage or silting up of the measurement point. The sensor states classified in accordance with the Namur NE 107 protocol are shown on the graphic display using a colour-coded display and Namur-defined symbols. They can be transmitted via Modbus, integrated modem and alarm management system as well as via error message outputs.

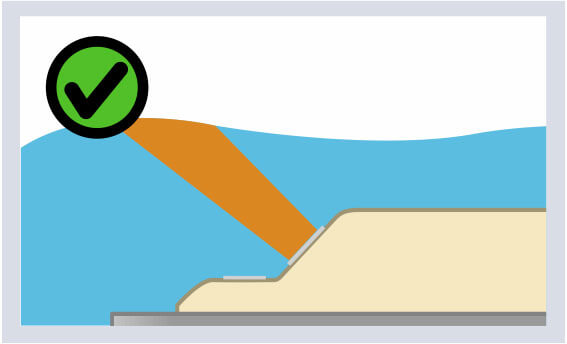

Sensor in working order

- Functionally reliable measurement within the specification

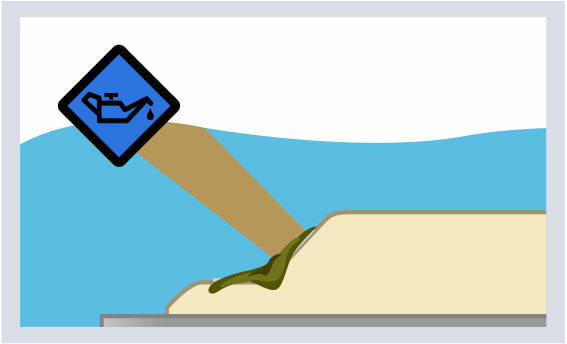

Maintenance required

- Unspecific sensor behaviour (incrustations, disturbances in front of the sensor)

- Measurement works, but should be checked

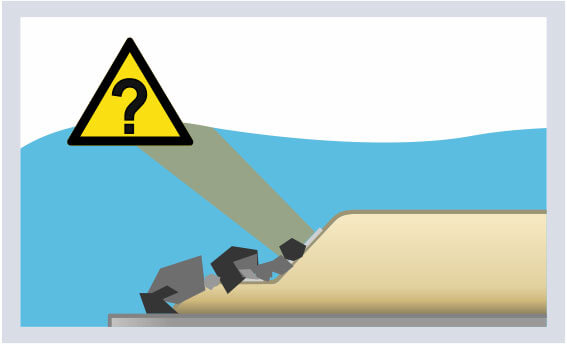

Sensor outside the specification

- Wear/spillage

- Sensor damage

- Impending measurement failure

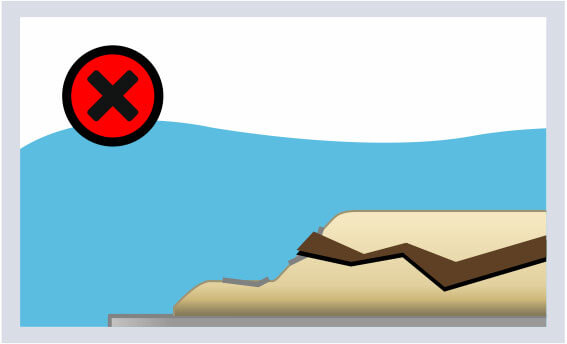

Sensor not in working order

- Mechanical sensor damage

- Electronic damage

- Massive wear

- Sensor destruction

IoT-Ready Flow Measurement

| Common | |

|---|---|

| Power supply | 100...240 V AC, -15 % / +10 %, 47...63 Hz or 10...35 V DC |

| Power supply connection |

|

| Maximum power consumption |

|

| Typ. power consumption |

|

| Enclosure | DIN Rail

Field Enclosure

|

| Protection | DIN Rail

Field Enclosure

|

| Operation conditions |

|

| Operation altitude | AC unit for use at altitudes up to 3000 m above MSL. For relay voltages >150 V, use is restricted to altitudes up to max. 2000 m above MSL (AC and DC units) |

| Operating temperature |

|

| Storage temperature | -30°C ... +80°C |

| Max. ambient temperature for installation and operation | +50 °C |

| Max. humidity | 80%, non-condensing |

| Parameterisation / Programming | Menu-driven using rotary pushbutton an two function keys, in English, German, French, Italian, Spanish, Portuguese, Swedish, Danish, Finnish, Polish, Hungarian, Romanian, Czech, Russian, Korean and Chinese language |

| Display |

|

| Connection |

|

| Inputs |

|

| Outputs |

|

| Controller | 1x 3-step controller, quick close control, adjustable slide valve position in the event of an error (controller only available for Types SR/GR/M3/G3/M9/G9) |

| Data memory |

|

| Storage cycle | 30 seconds to 15 minutes |

| Communication |

|

Specifications subject to change.

Brochure | NivuFlow 750

High accurate flow measurement for slightly polluted and dirty media in part filled and full pipes, channels and more.

![[Translate to English:] NivuFlow 750 IoT ready [Translate to English:] IoT ready NivuFlow 750](/fileadmin/_processed_/6/3/csm_NivuFlow-meter-iot-ready_b1bdf0b2c1.jpg)